Photochromics

LCR Hallcrest is able to supply a range of materials that change in response to different wavelengths of UV light such as sunlight. (A more irreversible photochromic is potentially available on request for certain applications).

These photochromic products can be used to create a range of effects changing from colorless to a wide range of colors in their activate, “excited”, state when exposed to sunlight by an outside UV source such as sunlight allowing an untold number of applications.

Photochromic products in their raw state can be difficult to use so for some applications we microencapsulate them enabling them to be used in a wider range of applications.

Photochromics are available in the following formats:-

- Dyes For direct use in materials able to utilize them

- Slurries Micro-encapsulated for use in aqueous systems

- Powders Micro-encapsulated for use in non-aqueous systems where protection is required

- Inks For printing onto papers, plastics and textiles

- Labels Used on finished products

- Masterbatch For addition to plastic molding and extrusion

Photochromic inks, dyes and masterbatches change their molecular structure and darken on exposure to specific types of light of sufficient intensity, most commonly ultraviolet (UV) radiation. In the absence of activating light they return to their clear state.

Photochromic dyes reversibly change color upon exposure to ultraviolet light in the range of 300 to 360 nanometers.

Reversible photochromics are found in applications such as toys, cosmetics, nail varnish, ophthalmic and sunglass lenses, textile clothing and garments, footwear, packaging, glassware, ceramics, plastics, security, and industrial applications.

Photochromic dyes can be applied to fabrics through conventional printing and dyeing methods.

When used in textile ink printed onto clothing garments such as t shirts, the change to color when exposed to sunlight occurs within 15 seconds or less, and returns to a near invisible clear shade after 5 minutes or less indoors when removed from the uv/sunlight.

Photochromic dyes can be mixed together to make an assortment of shades.

Photochromic masterbatch in pellet form can be dosed into injection molded plastic items, or into plastic extrusion.

The strength of the color change will increase as the plastic thickness increases.

Photochromic means ‘ability to change color when exposed to sunlight’. Photochromic dyes generate dynamic reversible color change under the sunlight or ultra violet (UV) light in the range of 300 to 360 nanometers. When placed into sunlight, or ultra violet rays, the molecular structure changes allowing the photochromic compound to turn into a darker color. The effect is reversed when the light source fades. The speed at which the dyes fade back to become colorless depends on the ambient temperature, and chemical structure of the dye.

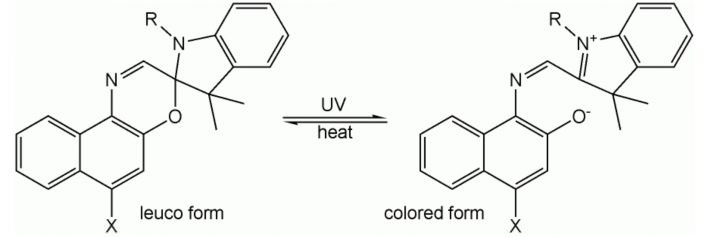

Spiropyrans and Spirooxazines

The spiro form of an oxazine is a colorless leuco dye; the conjugated system of the oxazine and another aromatic part of the molecule is separated by a sp³-hybridized “spiro” carbon. After irradiation with UV light, the bond between the spiro-carbon and the oxazine breaks, the ring opens, the spiro carbon achieves sp² hybridization and becomes planar, the aromatic group rotates, aligns its π-orbitals with the rest of the molecule, and a conjugated system forms with ability to absorb photons of visible light, and therefore appear colourful. When the UV source is removed, the molecules gradually relax to their ground state, the carbon-oxygen bond reforms, the spiro-carbon becomes sp³ hybridized again, and the molecule returns to its colorless state.

This class of photochromes in particular are thermodynamically unstable in one form and revert to the stable form in the dark unless cooled to low temperatures. Their lifetime can also be affected by exposure to UV light. Like most organic dyes they are susceptible to degradation by oxygen and free radicals. Incorporation of the dyes into a polymer matrix, adding a stabilizer, or providing a barrier to oxygen and chemicals by other means prolongs their lifetime.